Summary:Customized Plastic Car Lights Mould Suppliers

If you're planning to produce your own headlight, a custom-made plastic mould is the best solution. With the help of this mould, you can create an excellent-looking car headlight. In fact, it's quite eas......

Customized Plastic Car Lights Mould Suppliers

If you're planning to produce your own headlight, a custom-made plastic mould is the best solution. With the help of this mould, you can create an excellent-looking car headlight. In fact, it's quite easy to design and create such a mould. Here's how. Let's start with a few tips on the subject:

If you want to create a unique and durable car light, automotive

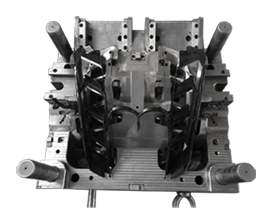

custom plastic car lights mould supplier can provide you with the best solutions. These moulds are ideal for custom plastic car parts and require perfect contours and mirror-like surfaces. In addition, automotive custom plastic car lights mould suppliers offer compression molding and resin transfer moulding services as well as other services to the aerospace sector.

Robotic system integrates into the injection molding cell, requiring only one control system and programming language for the robot. The advantages of this integrated system include cycle time savings and reduced integration costs. KUKA robotics also produce plastic fans in an injection molding cell. Increasingly, manufacturers are using carbon fiber reinforced plastic to enhance fuel efficiency and reduce weight. Carbon fiber parts are more rigid than steel, and offers custom solutions that meet these specifications.

Automotive custom plastic car lights mould supplier features include vertical, horizontal and e-insert machines. Both are able to produce precision parts while still remaining compact. The e-insert, for instance, features a hydraulic ecodrive and an innovative hydraulic injection unit. These moulds are ideal for high-end automotive parts. With such versatility, they have become a valuable source of custom plastic car lights mould suppliers.

Yaxin Mould

There are many benefits to working with Yaxin Plastic Car lights mould suppliers. Apart from its superior quality and excellent price, they have an excellent after-sales service. These mold suppliers are located in Huangyan, China. You can contact them to discuss your requirements. You can also choose the design, material, color and size that you want. And they have excellent customer service, so you can rest assured that they can meet your expectations and needs.

Suntime Precision Mould

The custom car taillights mould that Suntime Precision designed took 4.5 weeks to produce. The biggest challenges were tooth profile and warpage. The mould was then finished through a series of steps including CNC machining, wire cutting, EDM, drilling, polishing, and finishing. Here are some case studies from real customers. Each of the steps takes around two weeks. The final product has all the hallmarks of a Suntime Precision Customized Plastic Car lights mould supplier.