Summary:

The manufacturing process of an Auto Lamp Injection Mould requires metal moulds. While this process can be expensive, it is worth it to manufacturers, as mass production of moulds saves costs. Go4mould has the materials and skills to meet your moul......

The manufacturing process of an Auto Lamp Injection Mould requires metal moulds. While this process can be expensive, it is worth it to manufacturers, as mass production of moulds saves costs. Go4mould has the materials and skills to meet your moulding needs. Read on to learn more about the benefits of auto lamp moulds. Alternatively, contact go4mould today. Here are some things to consider when choosing an Auto Lamp Injection Mould:

A plastic injection mould is the most common type. Plastic mould materials include PC, ABS, PET, and NAK80. The design software used is UG, PROE, and CAD. The establishment of this company dates back to 1996. It employs advanced equipments, including CNC. GARGI INDUSTRIES is a Trade India verified seller and has extensive experience in manufacturing Plastic Auto Lamp Injection Moulds.

The design of an Auto Lamp Injection Mould requires a high-speed machine. The machine tool needs to have a high spindle speed of at least 20,000 revolutions per minute. The mold is produced in small batches. Delivery time is about 15 to 20 days. For large orders, it can take more than 30 days. To ensure that the product meets your requirements, consult with the Mold Supplier. There's no better way to get started.

Among the most common automotive parts, a car lamp is made of a headlight and a lampshade. The base is typically made of thermosetting plastic materials, while the lampshade is made of PMMA, PP, ABS, or a combination of the two. Two-color automotive lamp injection molding requires special attention. In addition, the center distance of the two screws in the mold must match. Lastly, a mold must be compatible with both the plastic parts and the lamp holder hole.

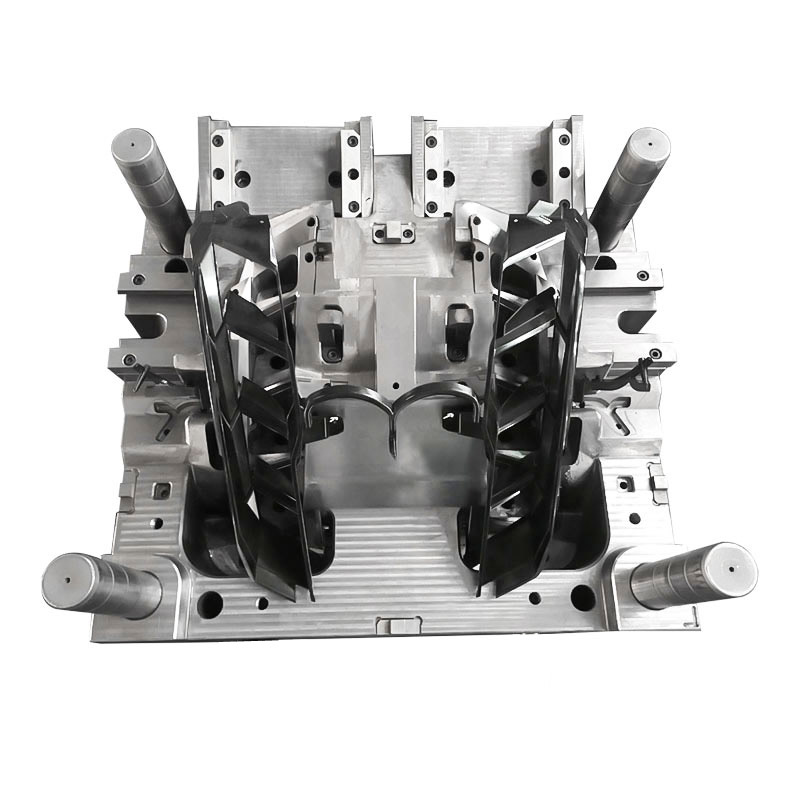

The surface of the Auto Lamp Injection Mould is highly detailed. It features a decorative frame, which is part of the headlight. It is assembled with a lens, which is visible through the lens. The surface of the mould needs to be highly electroplated. The design of the Auto Lamp Injection Mould should be attractive and resistant to high temperatures. If you are looking for a quality Auto Lamp Injection Mould, Xs Plastic Mould is the place to turn to.

Multilayer injection molding is a great way to reduce the time and cost of manufacturing an Auto Lamp. The article summarized the benefits of multilayer injection molding and explained the existing multilayer injection processes. Unlike conventional sandwich technologies, multilayer injection molding can overmold the first layer of the product on one side or both sides. It can also bond two previously separate layers. The advantages of multilayer injection molds can include lower production costs and faster production.

The design of a Car Lamp Injection Mould is a massive task that requires precision processing machines and special processes. There are several components of the Auto Lamp Injection Mould including a cooling system, eject system, and hot runner. There are also a variety of different coatings and each one has its benefits. For a high-quality Auto Lamp Injection Mould, you need to choose a company that specializes in making molds for automobile parts, household appliances, and industrial products.