Summary:Three Significant Differences Between Chinese Home Appliance Moulds and Western Home Appliance Moulds

China's home appliance mould industry has grown rapidly over the past decade, with backbone enterprises reaching international standards in some as......

Three Significant Differences Between Chinese Home Appliance Moulds and Western Home Appliance Moulds

China's home appliance mould industry has grown rapidly over the past decade, with backbone enterprises reaching international standards in some aspects of mold design and processing. The Chinese home appliance industry is growing rapidly, and is challenging the world's established giants. In this article, we will examine how Chinese home appliance moulds differ from their western counterparts. Here are three of the most notable differences. To understand these differences, we need to first consider the role of home appliance moulds in the home appliance industry.

The development of home appliance mould technology is primarily due to the increasing output of home appliances and the growing aesthetic demands of users. Consumers are increasingly demanding of products with curved surfaces and deep cavity designs. These changes in home appliances are reflected in the R&D and manufacturing levels of the home appliance mould industry. These factors have created a more dynamic environment for domestic mold companies, allowing them to better communicate with regional enterprises. In addition to the evolution of domestic mold technologies, home appliance mould companies must focus on the development of new mold technologies.

Chinese home appliance mould manufacturing has been accelerating the pace of technological upgrading. High-quality mould requires high-technology equipment and processes. This enables home appliance mould producers to create new designs and innovations. SINCERE TECH, a world-renowned plastic mould maker, provides home appliance mould to Chinese manufacturers and plays a key role in the home appliance industry. It is imperative that you choose a mould manufacturer with proven manufacturing capabilities.

The use of plastic injection molding in household appliances has led to numerous improvements in product design. This process allows manufacturers to produce high-quality plastic parts at a high rate. The design of home appliance moulds can be complex, and mold makers can add inserts, fillers, and additional components. Additionally, the manufacturing process is rapid and reliable, and after its completion, molds are used indefinitely. In addition to being versatile, these moulds allow manufacturers to create more advanced products and increase their profits.

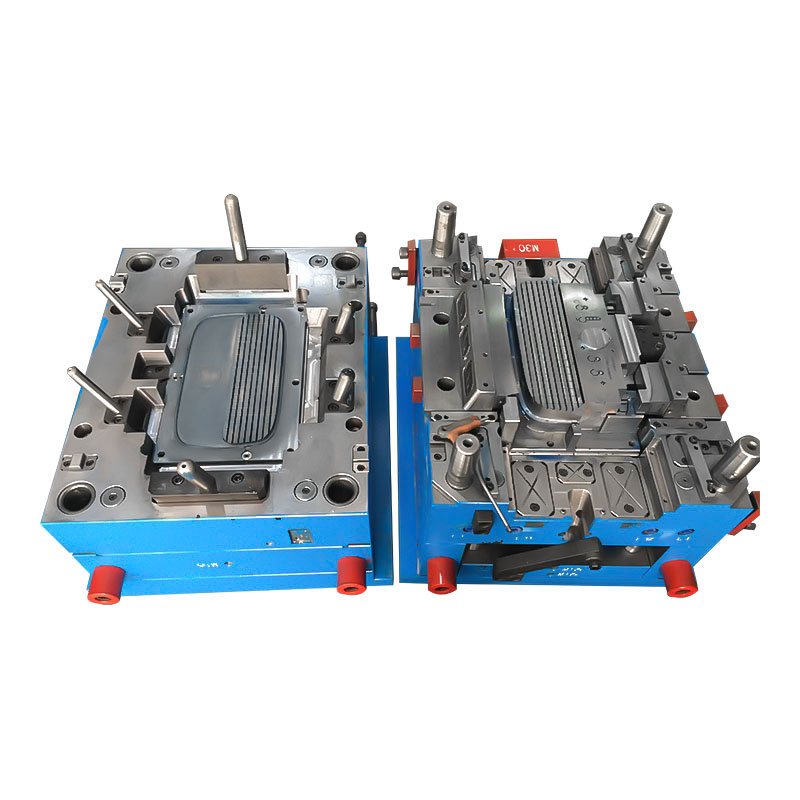

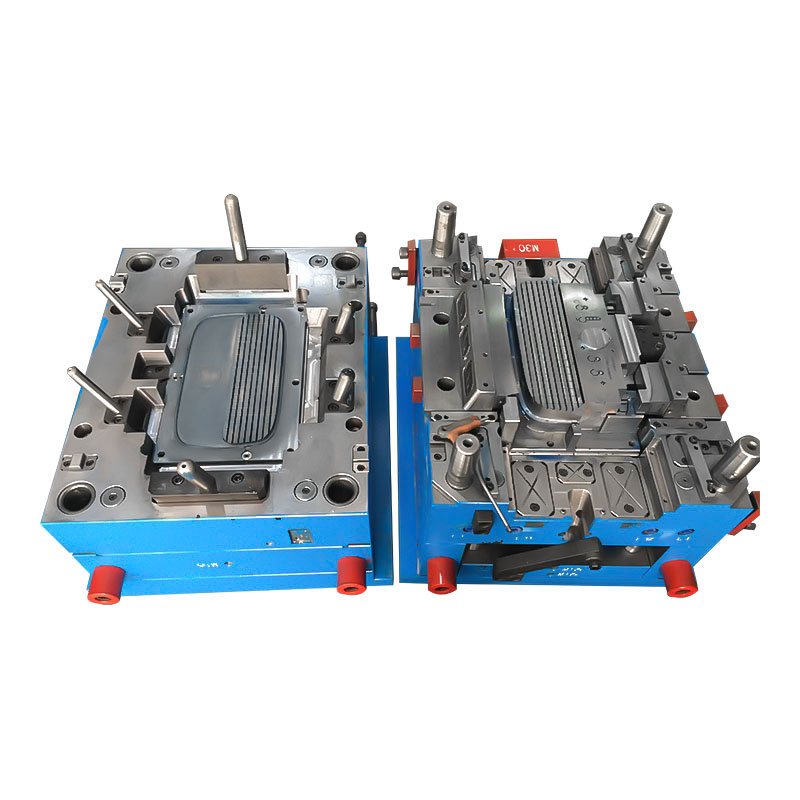

Low Cost Or Price Low Quantity, Low Volume AcceptedHome Appliance Mould MZ-19167

Low Cost Or Price Low Quantity, Low Volume AcceptedHome Appliance Mould MZ-19167

Product Details

| Location: |

China |

| Business Type: |

Manufacturer, Exporter |

| Brands: |

Classic |

| Certificate: |

CE, ISO9001 |

| Model: |

OEM |

| Terms of payment and delivery: |

Consultation |

| Minimum order quantity: |

1000PCS |

| Price: |

Consultation |

| Packing details: |

Packed in bags or cartons |

| Delivery time: |

25days |

| Payment method: |

TT L/C... |