Summary:

When it comes to plastic moulding, there are a few options to choose from. The main types of plastic moulding include rotational moulding, injection moulding, blow moulding, and compression moulding. Some of these methods are more expensive than oth......

When it comes to plastic moulding, there are a few options to choose from. The main types of

plastic moulding include rotational moulding, injection moulding, blow moulding, and compression moulding. Some of these methods are more expensive than others, but they can help you produce a high quality product at a competitive price.

Rotational moulding is often used for big hollow parts. This is because the process is efficient at material usage. Another benefit of this method is that it is environmentally friendly. It's also a cost effective way of producing large volumes.

Injection moulding is a popular method for making high volume plastic parts. This technique uses a liquid plastic that is heated to a temperature and poured into a shaped mould. Afterwards, the liquid is cooled and removed from the mould. Depending on the application, this process can produce a variety of products. These can range from PVC pipes to straws. However, this process is only effective for some types of parts.

Blow moulding is another common technique, especially in large-scale production. In this process, a machine nozzle or fan will blow a stream of air into the plastic to heat it. The liquid is then pressed against the walls of the mould to form a shape. Afterwards, the mould is trimmed to remove the mold.

A newer, more efficient process involves using a hot runner. This process allows the plastic to be formed at a lower injection pressure. In addition, this can help with plastic that may be placed in corners. Using a hot runner also can shorten the molding cycle.

Flow analysis software is useful for the plastic moulding process. It can calculate the most efficient flow for a particular part and make sure that the mould is capable of producing the best possible results. Similarly, an advanced mechanical ejection mode can improve the motion of the plastic part.

Whether you're working on a small or large-scale project, it's important to know the most effective plastic moulding processes. In addition to the best method for a specific job, you need to consider other factors like the cost of production, the time required to produce each component, and whether it's worth the investment. While the best method might be the most costly, it may be the most efficient.

Another thing to consider is whether you want to use a hot runner or a cold runner. If the mould has a larger diameter, a hot runner can be more efficient. Hot runner molds also allow for smaller shots, which means less metering time. Also, you can use a hybrid system that combines hot and cold runners for your project.

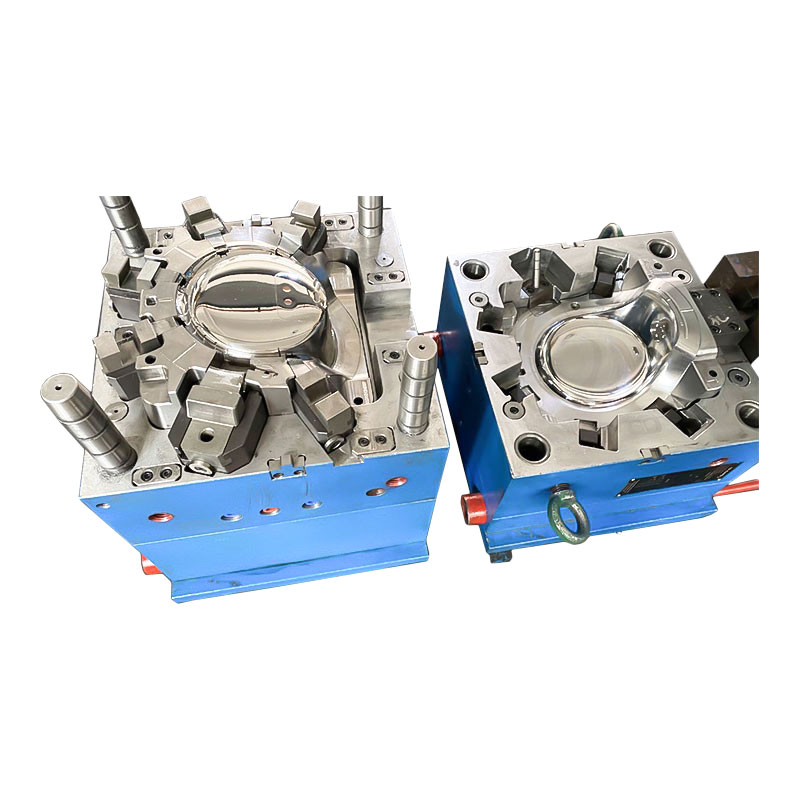

As with any mold, a plastic crate injection mould needs to be well-made to ensure high performance. The materials should be a strong, durable and flexible alloy. Additionally, you should choose a company that has a proven track record of providing high-quality, dependable moulds.

The plastic crate mould is a useful tool for the transportation of food, beverages, eatables and other items. Normally, the mould is made from HDPE. This material is a high-quality material with a low temperature performance and strong tensile strength.