Summary:

Custom Plastic Moulding is a process that produces custom plastic parts. The first step is to determine the materials needed for the custom plastic part and the mold. There are several tools available for this process, including hard tooling, soft ......

Custom Plastic Moulding is a process that produces custom plastic parts. The first step is to determine the materials needed for the custom plastic part and the mold. There are several tools available for this process, including hard tooling, soft tooling, and single cavity pull-ahead tooling.

Mold-making is an easy process, but it requires quality control. Ultimately, the mold must meet the customer's specifications. Once the mold is complete, it becomes the finished product. Custom plastic moulding is a process that is not done by just anyone. The process requires a skilled professional with a lot of technical knowledge and experience. A plastic moulder should be able to walk a customer through the entire process.

Custom Plastic Moulding can be performed on a wide range of materials. Some of these materials include wood, plastic, and metal. The materials used for moulds should be durable and wear-resistant. The length of production will also determine the material used. A durable mold is necessary for production operations involving abrasive materials.

The process begins with the loading of resin pellets in the barrel. These pellets are heated to melt and flow. They are then injected into the mold's runner system. Once the plastic part is cooled sufficiently, the mold is closed. The technician closing the mold must pay attention to the process and consider any impediments that could hinder the process. Double checking the mold is also recommended.

The selection of plastic material for custom plastic molding is one of the most important decisions to make. The expert advice of an ICOMold representative will help you choose the right material for your project. This choice can affect the final product's performance and price. Different types of materials have different properties and will react differently to different circumstances.

Custom Plastic Moulding is a versatile, cost-effective method of making plastic parts. It's a quick and simple process and can be done in large quantities. Custom plastic injection moulding is a great way to manufacture complex or small plastic parts. For example, it is an economical way to make thousands of parts in a short period of time.

The tooling used to create a custom plastic mould can account for up to 70% of the initial start-up cost. Choosing the wrong mould material can make or break your dream. Rotational Plastics offers affordable steel and aluminium moulds that are perfect for custom plastic moulding. A well-done custom plastic mould can help you turn your idea into a reality.

When designing your custom plastic mould, there are a few steps to make it easier. First, you need to choose a material that can withstand the injection molding process. If you're working on a prototype, the best material to use is a durable thermoplastic polymer.

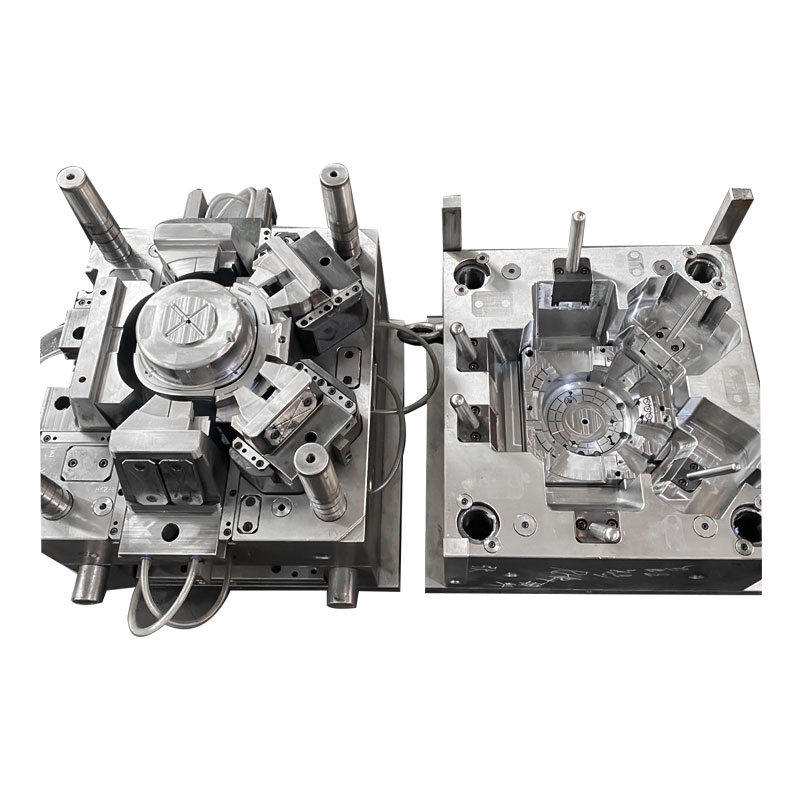

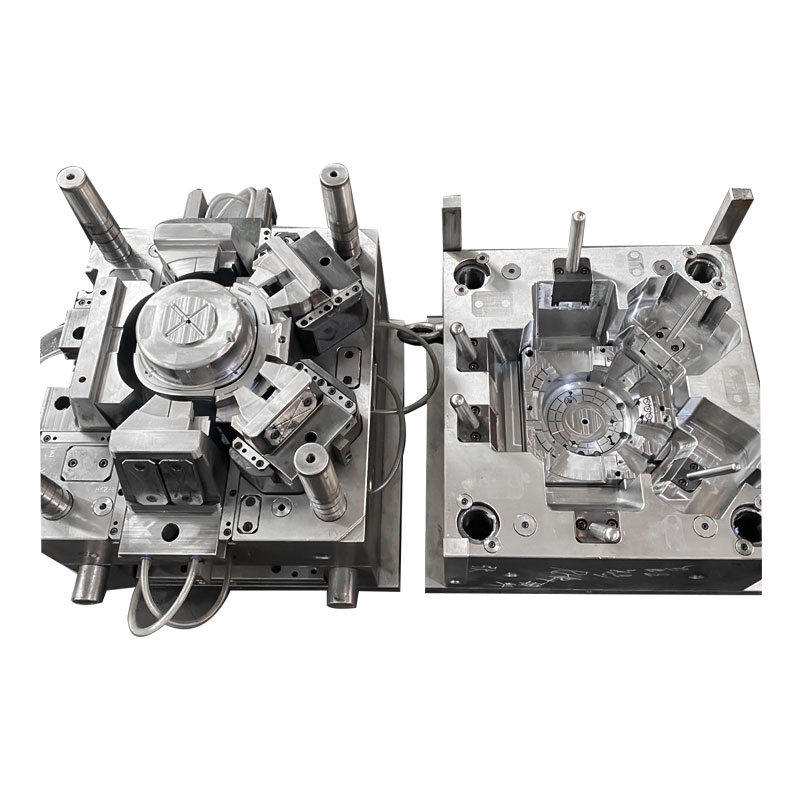

High Quality Plastic Injection Mould Air Fryer

High Quality Plastic Injection Mould Air Fryer

| Location: |

China |

| Business Type: |

Manufacturer, Exporter |

| Brands: |

Classic |

| Certificate: |

CE, ISO9001 |

| Model: |

OEM |

| Terms of payment and delivery: |

Consultation |

| Minimum order quantity: |

1000PCS |

| Price: |

Consultation |

| Packing details: |

Packed in bags or cartons |

| Delivery time: |

25days |

| Payment method: |

TT L/C... |