Summary:Choosing a Company to Provide Custom Plastic Moulding

One of the most important things to consider when choosing a company to provide Custom Plastic Moulding is the lead time. The longer the lead time, the more costly the product will be. In additio......

Choosing a Company to Provide Custom Plastic Moulding

One of the most important things to consider when choosing a company to provide Custom Plastic Moulding is the lead time. The longer the lead time, the more costly the product will be. In addition, choosing a manufacturer outside of your production area increases the lead time. If you need your molded products right away, consider finding a mold maker who offers packaging and shipping. Shipping time can be reduced, but the longer the lead time, the higher the cost will be.

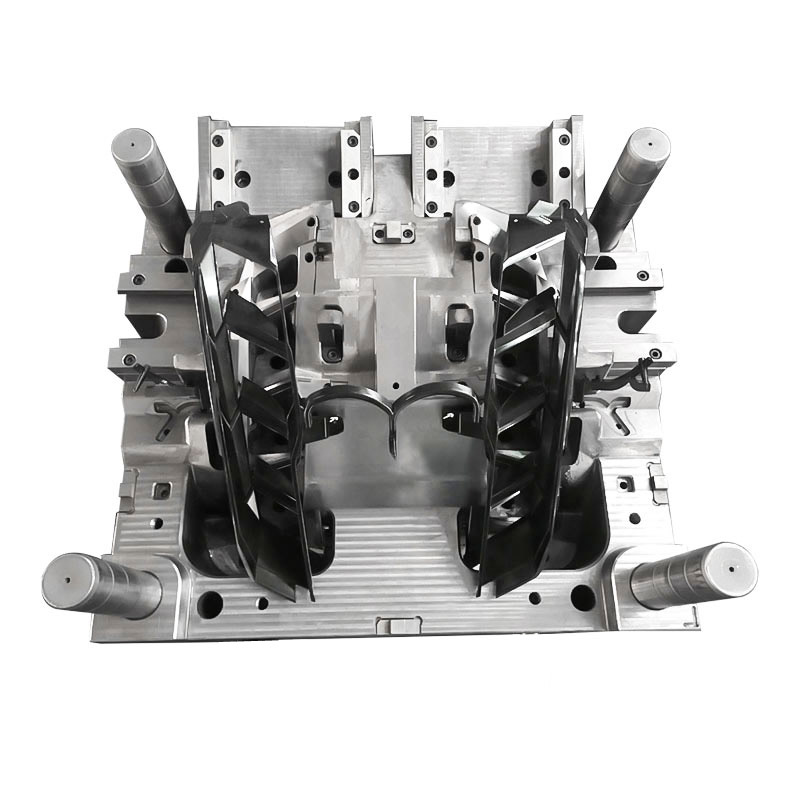

The process of plastic injection molding begins with a team of industrial engineers designing a custom mold. Once the design is approved, the mold is filled with various types of plastics. Once the mould is filled, unique branding can be added to the finished product. Plastics are the preferred material for many types of packaging, from pharmaceutical bottles to food containers. If you need a custom plastic product for your product, you can choose an American company for the job.

Quality tooling is another important factor in ensuring superior quality products. Quality tooling includes several operations such as the base of the mould and hot tips and runners. Once the initial sample is approved, mass production begins. Molds must be carefully maintained to ensure a long life and consistent quality. Choosing a company with quality molds and services is a great way to ensure a long-lasting product. Once you've chosen a company, be sure to check their references.

Injection molding is a popular method for producing high-volume plastic parts. From car parts to surgical parts, injection molding produces flexible and durable parts. Injection moulding is a high-volume production method that can be expensive if you don't use a mold made from steel or aluminum. But once your production volume reaches a certain level, the cost per unit drops significantly. So, if you're interested in a custom plastic moulding company, contact a reputable company that can provide you with a quote today.

While custom plastic injection molding is an advanced technique, its lead time and cost are not the only factors to consider. Using a company that specializes in this process ensures your product's quality and efficiency. In addition to the cost benefits, custom plastic injection molding is also highly automated and fast. A good mold can be as strong as a metal part, and the injection molding process makes it easy to produce large volumes of parts quickly and consistently.

The main advantage of plastic injection molding is its ability to mass-produce products of high quality and precision. Injection molding can produce millions or even thousands of precision plastic parts, and it offers a high degree of repeatability and a quick turnaround time. Because the process is automated, there is very little waste and the cost of production is reduced dramatically. Injection molding is the most effective option for low-resiliency parts and large volumes.