Summary:Auto Lamp Injection Mould

An Auto Lamp Injection Mould is a hollow cavity made of metal or plastic that is used for the manufacturing of an auto lamp. The material used for manufacturing the Auto Lamp Injection Mould is brass, aluminum, plastic or s......

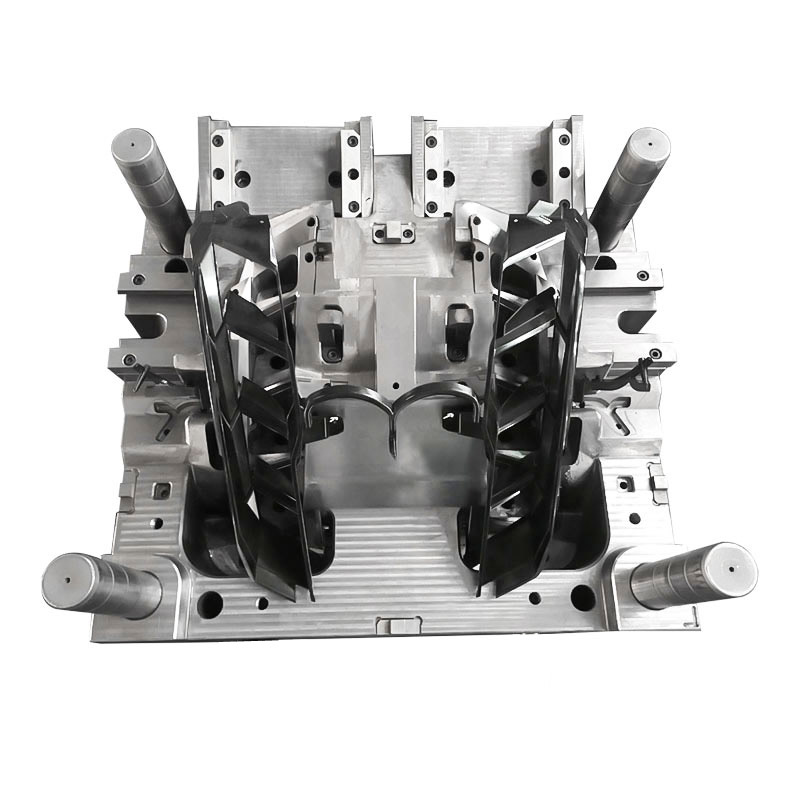

Auto Lamp Injection Mould

An Auto Lamp Injection Mould is a hollow cavity made of metal or plastic that is used for the manufacturing of an auto lamp. The material used for manufacturing the Auto Lamp Injection Mould is brass, aluminum, plastic or steel. The design of the mould is an essential part of the manufacturing process.

Auto Lamp Moulds are important for the manufacturing of automotive lamps. This type of mould is designed for simple geometries and produces high surface finish. Injection moulding has several advantages, including cost-effective aluminium moulds and quick turnaround times. Manufacturers can reduce the costs of the moulds by using advanced technology, such as CNC machining and rapid tooling.

The Auto Lamp Injection Mould is manufactured by Gargi Industries, a reputed Indian manufacturer of plastic moulds. They have an extensive customer base in India and are Trade India verified. They provide customised solutions to their customers. They are committed to delivering quality results with a perfect blend of human expertise and automation.

Auto Lamps are crucial to the overall aesthetics of a car. A car lamp typically has a headlight body, a reflector, a decorative frame, and a lamp lens. The headlight body has very high design standards, and the mold must be designed and manufactured to be aesthetically pleasing. For example, an Audi car lamp was the first car to introduce daytime running lights. In addition to enhancing the appearance of cars, auto lamps are increasingly being used as a design signature.

The process of designing a mould includes many stages, and each one involves careful attention to detail. The design process begins with a 2D draft. Once the final mould is approved, the next step is to deposit a 40% deposit via T/T and await the delivery of the mould. The delivery time for a small batch is typically 15 to 20 days.

Plastic Injection Mould technology is a fast way to manufacture automotive lighting components. It produces components that are nearly identical, has high-quality surface finishes, and can be processed in high or low volumes. It also allows for prototypes to be created in a very short period of time, and is ideal for creating high-quality designs.

Injection moulding can produce a variety of materials, such as glass, metal, and thermoplastic polymers. Its process is environmentally friendly, requiring very little energy. And it can create extremely durable products. Unlike traditional manufacturing processes, injection moulding is cost-effective for small-volume production.

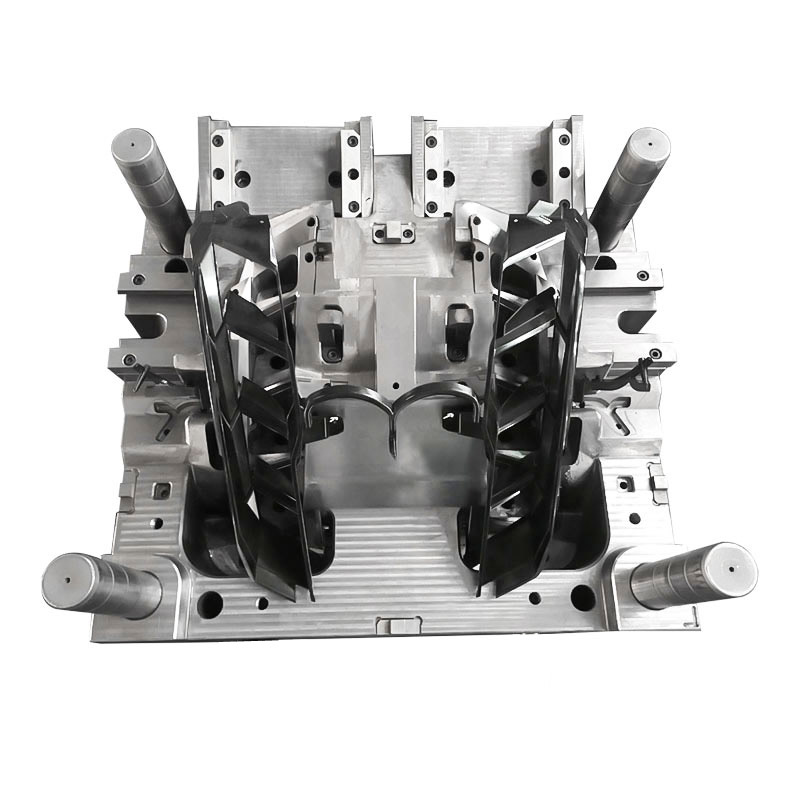

Customized Plastic Car Lights Mould

Customized Plastic Car Lights Mould

Product Details

| Location: |

China |

| Business Type: |

Manufacturer, Exporter |

| Brands: |

Classic |

| Certificate: |

CE, ISO9001 |

| Model: |

OEM |

| Terms of payment and delivery: |

Consultation |

| Minimum order quantity: |

1000PCS |

| Price: |

Consultation |

| Packing details: |

Packed in bags or cartons |

| Delivery time: |

25days |

| Payment method: |

TT L/C... |

The products displayed on the official website are all produced by us. You can order directly according to the existing specifications. or you can contact us by email to customize according to your shape, size and material. We will provide you with the competitive price!