Summary:Car Bumper Mould

Car Bumper Mould is a mould used to produce bumpers for cars. It has two types, namely outer parting and internal parting. Outer parting is the conventional method for making bumpers. The parting surface is the largest contour line ......

Car Bumper Mould

Car Bumper Mould is a mould used to produce bumpers for cars. It has two types, namely outer parting and internal parting. Outer parting is the conventional method for making bumpers. The parting surface is the largest contour line in the main drawing direction. The outer parting mold has a simple structure, easy to eject, and a short molding cycle. However, the disadvantage is the higher risk of parting lines on the product. In addition, the mold needs to go through a polishing process, which increases the labor cost.

The process of making car bumpers begins with making a foam or cardboard mold. You will then hold your fiberglass sheet between two pieces of cardboard or foam. Once the mold is formed, you can cut the fiberglass sheet into the desired shape using a knife. Once the mold is ready, apply a coat of polyester primer and let it dry. Then, you will need to finish the mold by applying two or three coats of wax.

When looking for a car bumper mould, make sure it is made by a reputed manufacturer. Ensure that the mold is hard enough for the job. This will help you avoid problems later. The mold's hardness is crucial to a quality bumper. The material should be durable enough to withstand high temperatures.

Whether you need a rear or front bumper, a car bumper mould can be the perfect solution. These molds are available in various styles and sizes and can be delivered in a few weeks. A well-made car bumper mould will enhance the looks of your car and add to its value.

Injection molding process involves a variety of processes, from selecting raw materials to the closing of the mould. Next, the mould is sealed with a special mechanism. After this, the product is subjected to pressure and cooling. The injection process has increased production efficiency and the quality of car bumper finished products.

With advanced software, the design process for a car bumper mold can be optimized using simulation. Mold-Flow software is used to simulate the injection molding process of an automobile front bumper. It can also be used to optimize the number of gates and their placement in the automotive bumper mold. Injection molding simulation can help you design the most appropriate gate scheme and minimize the amount of trial molds.

Several important principles and design considerations govern the process of designing a bumper mold. A high-quality bumper mold is cooled uniformly and does not deform or warp. Hence, the cooling water circuit must be carefully designed and follow a strict design rule. It should also be able to regulate the mold's temperature.

Bumper molding is a process of molding a special polyurethane material in a large bumper mould. This method saves raw materials and reduces costs. It is similar to injection molding except that it uses thermosetting polymers. The polymer is then cured in the mold. Various auto parts are made using this process, including automotive bumpers, air spoilers, and fenders.

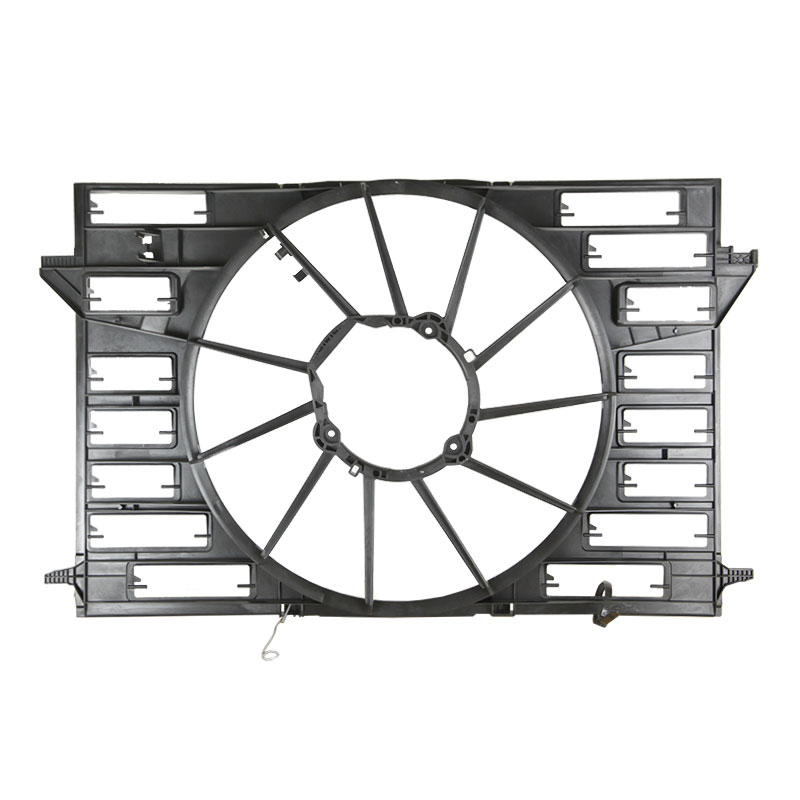

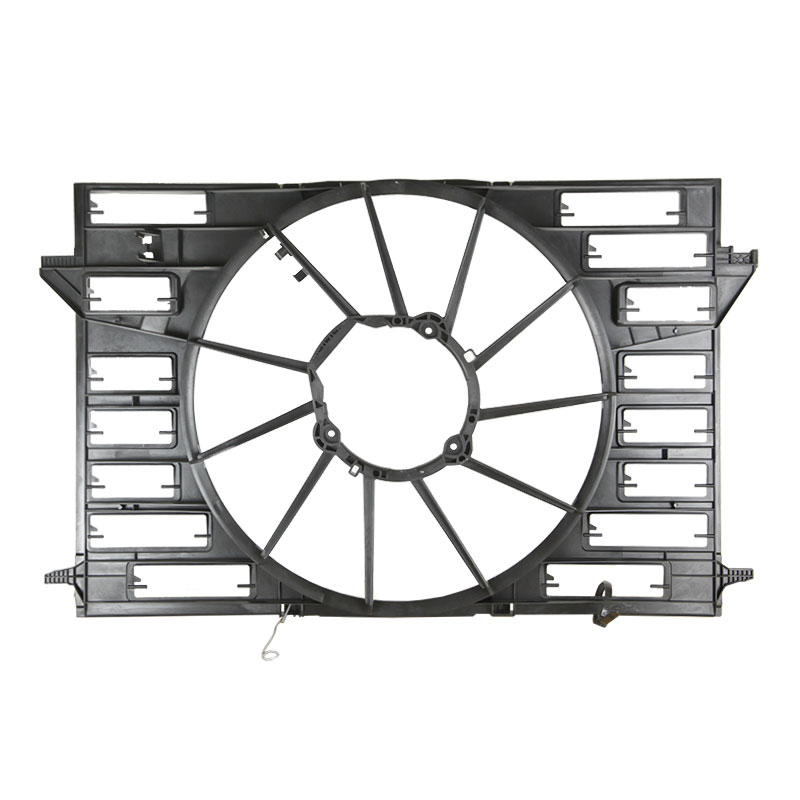

High Quality Oem CustomizedFan Mold Sample

High Quality Oem CustomizedFan Mold Sample

Product Details

| Location: |

China |

| Business Type: |

Manufacturer, Exporter |

| Brands: |

Classic |

| Certificate: |

CE, ISO9001 |

| Model: |

OEM |

| Terms of payment and delivery: |

Consultation |

| Minimum order quantity: |

1000PCS |

| Price: |

Consultation |

| Packing details: |

Packed in bags or cartons |

| Delivery time: |

25days |

| Payment method: |

TT L/C... |

The products displayed on the official website are all produced by us. You can order directly according to the existing specifications. or you can contact us by email to customize according to your shape, size and material. We will provide you with the competitive price!