Summary:The Benefits of a Car Parts Injection Mould

If you have ever wondered how the auto industry produces their parts, you may have considered the use of a Car Parts Injection Mould. Today, there are many benefits to this process. Not only does it produc......

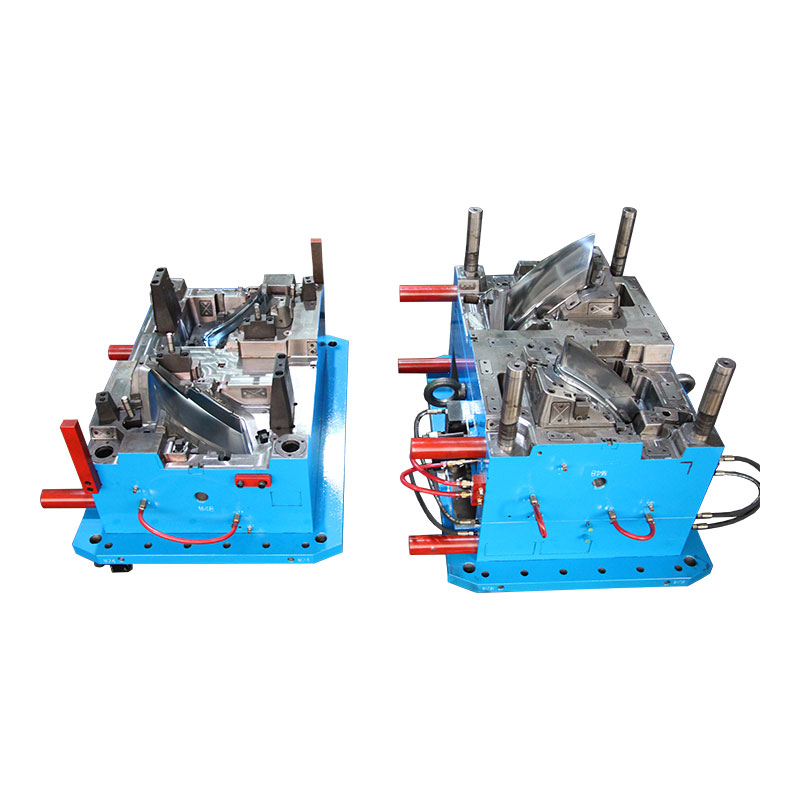

If you have ever wondered how the auto industry produces their parts, you may have considered the use of a Car Parts Injection Mould. Today, there are many benefits to this process. Not only does it produce thousands of car parts in a short period of time, it is also relatively inexpensive. Furthermore, it allows for greater customization. It is used in the production of many different types of car parts, including dashboards, fender flares, and more.

Injection molding is becoming increasingly popular in the automotive industry. It can produce interior and exterior plastic components, as well as under the hood. Car injection molding can also be used to produce components that improve the safety and fuel efficiency of a vehicle, while reducing the impact on the environment. Materials for automotive parts include polystyrene, polypropylene, and polycarbonate. The company will be able to advise you on the material that best meets your requirements.

There are several important factors to consider when selecting the right car parts injection mold. First, the materials to be used. The types of plastics used in injection molding can make or break a product. This means that it is critical to find a high-quality material. Once you've made a decision on which materials are best for your needs, you'll need to select the correct equipment. The right material will ensure that your product is as accurate as possible.

The car parts injection mold manufacturer can manufacture any part for a vehicle, including those that must contact different surfaces. Unlike other plastic manufacturing methods, injection molding is also cheaper over a large product run. Because you'll only be funding the materials, the mold's large up-front cost will quickly pay off. And if you only need to buy the materials, you'll soon be able to pay for the mold with minimal effort.

There are several important considerations when selecting the right material for your car parts injection mould. One of these is flexural modulus. This is the amount of flexibility, bendability, and heat deflection a material has. Flexural modulus is also important because it can affect the amount of water absorbed by a material. Plastics are generally more durable than metals and can be used to make more complex car parts.

The main advantage of an automotive injection mould is that it produces high-quality, lightweight car parts. These parts are often manufactured by automotive OEMs. They are usually high-demand and produced in high volume yields. Automotive injection moulding is ideal for high-volume automotive parts. They are strong and lightweight, which makes them popular with the automotive industry. But, there are also some drawbacks to this method. You might find that it isn't worth the money.

During the holding period, the material needs to cool. This is because a tool can overheat and create a hot part. Moreover, an improper heating or cooling system can also create a problem with hot runners. Insufficient ventilation, inadequate cooling, or an excessive amount of material can lead to hot runners. And, if you are making plastics, you should also pay attention to the gas vents.