Summary:Car Parts Injection Mould. The process involves rapid cycling between the material and the mould, causing the plastic to undergo non-uniform deformation. Because the pressure generated during the process is very high, intricate shapes can be produced......

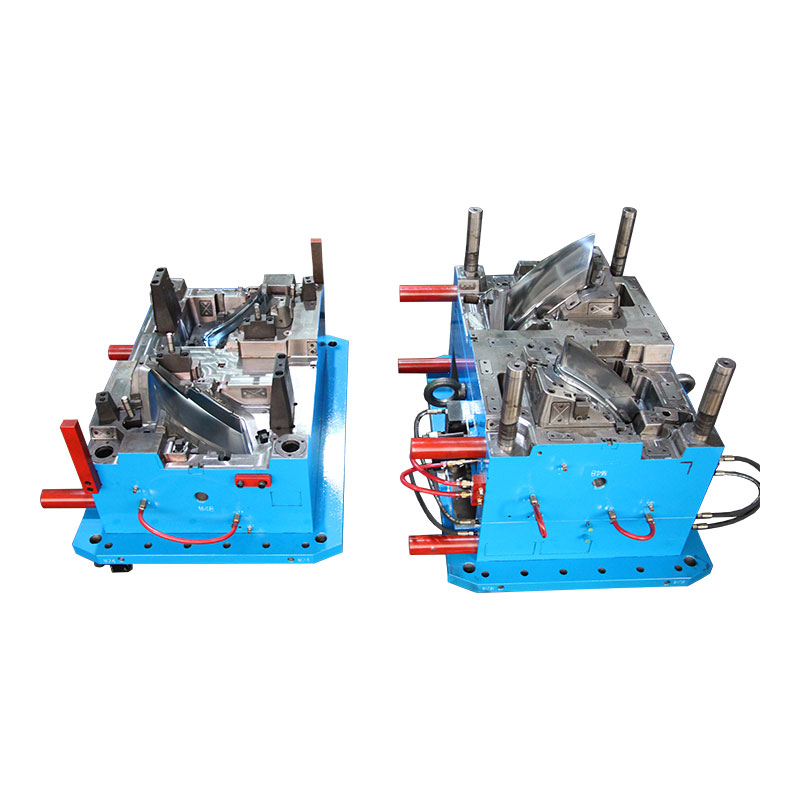

Car Parts Injection Mould. The process involves rapid cycling between the material and the mould, causing the plastic to undergo non-uniform deformation. Because the pressure generated during the process is very high, intricate shapes can be produced. The process requires prior design work to create accurate complex shapes. A good prior design considers wall thickness, corners and transitions, bosses, gate placements, and the position of vents and holes.

A plastic Car Parts Injection Mould is a highly versatile process, capable of producing a wide range of automotive parts. From fender flares to complex dashboards, car parts are produced from a wide range of materials. Injection molding is particularly advantageous because it is economical to produce thousands of automotive parts in a single mold. Additionally, it provides a high level of customization. And since the process uses plastics, it is also easier to scale for mass production.

One of the most important aspects of plastic injection molding is its durability. It can withstand extreme temperatures and road hazards, as well as constant abuse in the engine compartment. Additionally, plastic is easier to work with than metal, so the process can produce more parts in less time. The advantages of plastic injection molding cannot be overstated. If you're in the market for quality car parts, make sure you check out ICOMold!

Choosing the right process depends on the size of the part, dimensional tolerance, materials, and bonding and interior strengthening. Custom capabilities allow mid-production adjustments without compromising materials circulation. And, since car parts are a large part of a vehicle, it's imperative to choose the right injection mold for the job. And Kemal molds can offer you a quick and accurate quote. So, make sure to take the time to find a quality injection mold for your next project!

Injection molding is a highly versatile process. Compared to other plastic manufacturing methods, injection molding can handle a much higher degree of complexity. Unlike other methods, it is also cheaper for manufacturers over the long run because the mold costs so little and yields more parts. It's also more complex than other plastic manufacturing methods, which is great for automakers. Injection molding also saves on the cost of raw materials, which means that it's more cost-effective than ever before.

When choosing a mold maker, look for a manufacturer with real interest in your project. Look for a mold maker who communicates effectively with you via email and pictures. And make sure you choose a supplier who's been around for a long time. This way, you won't have to worry about quality issues. And you'll be able to take advantage of the booming Chinese economy. So, if you're ready to invest in a mold, start searching for the right supplier today! And don't worry - there are many benefits to acquiring a mold.

Besides being affordable, a high-quality car part injection mold is also more durable. With less labor costs, car makers can reduce their production costs while getting a better quality product faster than they could by traditional methods. This is a good thing, especially for those who are looking to save money on production. That means more money in their pockets! If you're looking for an easy way to make quality plastic car parts, look no further than injection molding.