Summary:How to Design an Automotive Mould.Here are a few options: polymer clay, sand, silicone, or a combination of all three. While 3D printing and silicone moulds are both great for small parts, injection molding offers better price per unit. Plus, as you ......

How to Design an Automotive Mould.Here are a few options: polymer clay, sand, silicone, or a combination of all three. While 3D printing and silicone moulds are both great for small parts, injection molding offers better price per unit. Plus, as you create more parts, your cost per piece decreases. This makes injection moulding an excellent choice for large-scale automotive projects.

The process of designing an automotive mould should focus on its functionality, structural stability, production safety, and convenience. Aside from functionality, other considerations include materials for the mould's main components, consistency of technical agreement requirements, and the ease of operation and debugging. Any manufacturing process can become more efficient and cost-effective if the mold factory is able to resolve issues and fix flaws. Listed below are a few of the most common automotive mould design problems and what to look for.

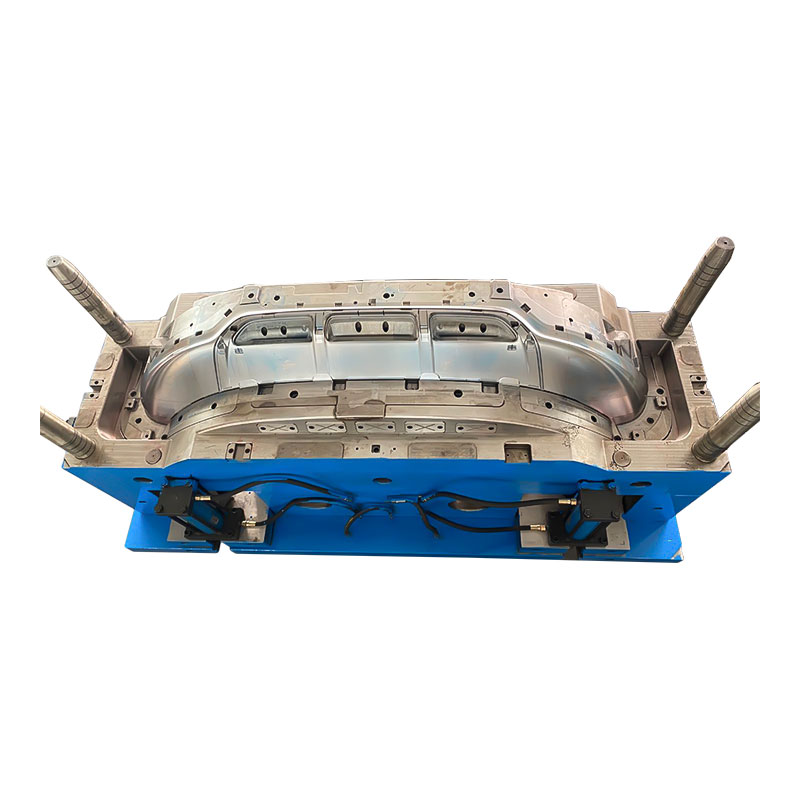

The most obvious part of an automobile mold is the cover. The term "automotive mould" encompasses several types of automotive molds, including stamping and injection molds. While it may be difficult to discern which type of mold is best for a given product, each of these types of molds has several distinct purposes. Its primary function is to manufacture a particular part of an automobile, which may be a component or an entire vehicle.

In China, the automotive mould industry is growing rapidly. It is the largest industry in China's automotive mould sector, with sales of more than 700 billion yuan in 2015. Foreign auto mould companies are stepping into the China auto mold industry to supply the nation's red-hot domestic and export market. The automotive mould industry in China is a great opportunity for foreign investors and domestic car makers alike. Just make sure to take advantage of the opportunities that exist.

The process of making a mould cavity starts with calculating the cost. To do this, you can compare existing car exterior and interior trim moulds. This method allows for easier comparisons, as you can use the same data for the new object. Moreover, you can avoid making any unnecessary changes once the mould has been formed. To calculate the cost, you must first determine the contour factor C. Next, you need to multiply this value by the number of cores that have an equal fitting area.

The automotive mould is helpful for the production of automotive parts. It is a great way to produce complex parts. Many parts are manufactured this way, including the interior and exterior structures of the car. This method is fast, scalable, and highly compatible with various types of plastics. These include ABS, polypropylene, acrylic, nylon, and acetal. Also, it allows you to create high-quality components that can withstand a beating.