Summary:In the pursuit of enhancing both safety and aesthetics in the automotive industry, significant advancements in car lights mould technology have taken center stage. Car lights, once primarily functional components, have now evolved into sophisticated ......

In the pursuit of enhancing both safety and aesthetics in the automotive industry, significant advancements in car lights mould technology have taken center stage. Car lights, once primarily functional components, have now evolved into sophisticated design elements that not only illuminate the road but also enhance the overall appeal of modern vehicles.

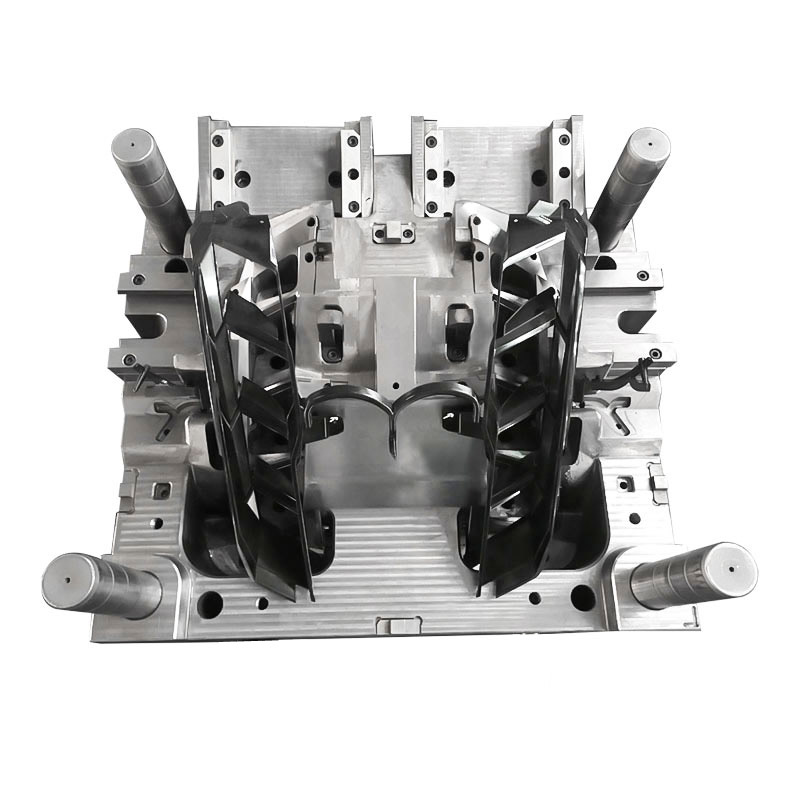

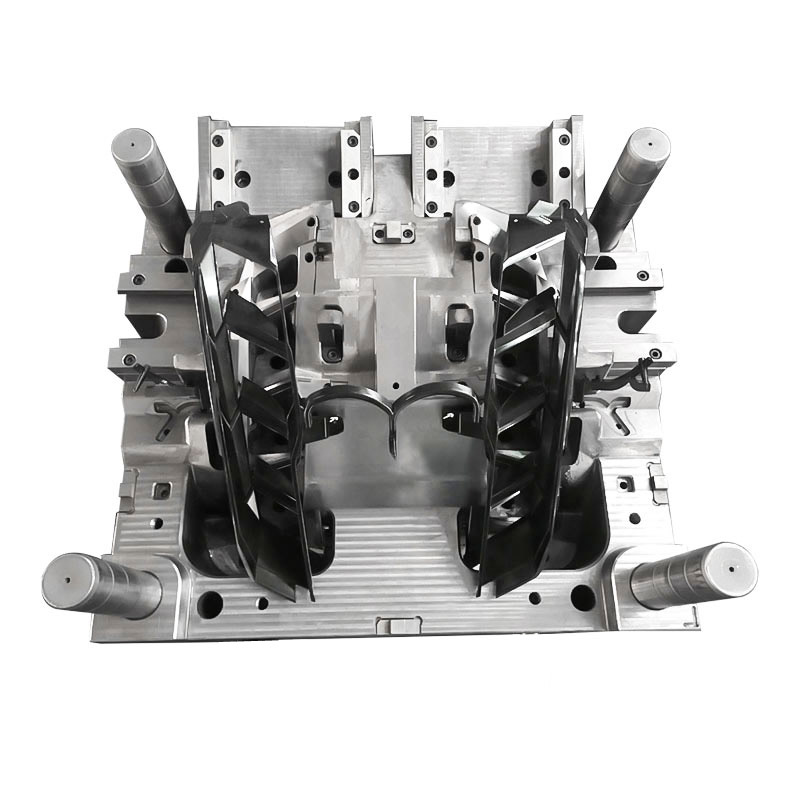

One of the key breakthroughs in car lights mould technology is the utilization of precision injection moulding. This technique allows for the production of complex shapes and designs with exceptional accuracy and repeatability. By injecting molten plastic or composite materials into precisely crafted moulds, manufacturers can achieve seamless and precise light housings, lenses, and other intricate components. This precision not only ensures optimal functionality but also enables the incorporation of unique and eye-catching design elements.

The integration of advanced materials in car lights moulds has also played a crucial role in transforming the automotive lighting industry. High-performance polymers, such as polycarbonate, have replaced traditional glass lenses due to their superior impact resistance, durability, and design flexibility. These materials allow for the creation of sleek and aerodynamic light designs while maintaining the necessary optical properties for optimal illumination.

Moreover, the introduction of LED (Light-Emitting Diode) technology has revolutionized car lighting systems. LED lights offer numerous benefits, including energy efficiency, longer lifespan, and improved visibility. Car lights moulds have been redesigned to accommodate the smaller and more compact LED modules, enabling automakers to incorporate advanced lighting features such as adaptive headlights, dynamic turn signals, and ambient lighting. These innovations not only enhance safety on the road but also contribute to the overall visual appeal of vehicles.

The advent of digital design tools and simulation software has further accelerated the development of car lights moulds. Automakers can now create virtual prototypes, simulate lighting performance, and optimize the distribution of light output. This allows for precise control of beam patterns, light intensity, and color, resulting in improved visibility for drivers and increased safety for all road users.

Furthermore, the introduction of additive manufacturing techniques, such as 3D printing, has facilitated the production of highly intricate car lights moulds. This technology enables the rapid fabrication of complex geometries and customized designs, which were previously challenging to achieve using traditional manufacturing methods. 3D-printed moulds offer faster prototyping, reduced costs, and increased design freedom, allowing for rapid innovation in car light designs.